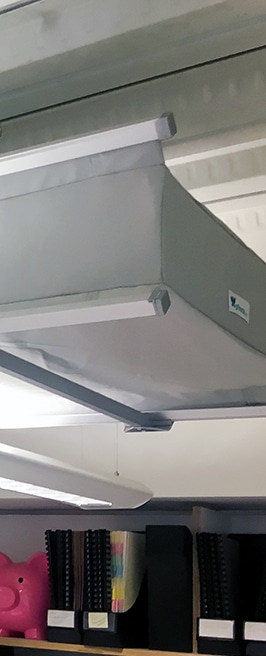

Fabric ducting is available in a variety of shapes to suit different applications and aesthetics. Round ducts are visually appealing but may take up too much height in a low-ceilinged office — in such cases, a half-round profile is often a better choice. In a server room, where large volumes of air need to be moved within a very

limited space between the servers and the ceiling, an elliptical duct (wide but shallow) may be the most effective solution.

In most cases, the application and surrounding conditions will naturally determine the most suitable shape.